American Natural Materials is one of very few suppliers offering a reliable & scaleable access to NFPP materials (Natural Fiber Polypropylene) suitable for applications in the automotive industry and similar industrial processes.

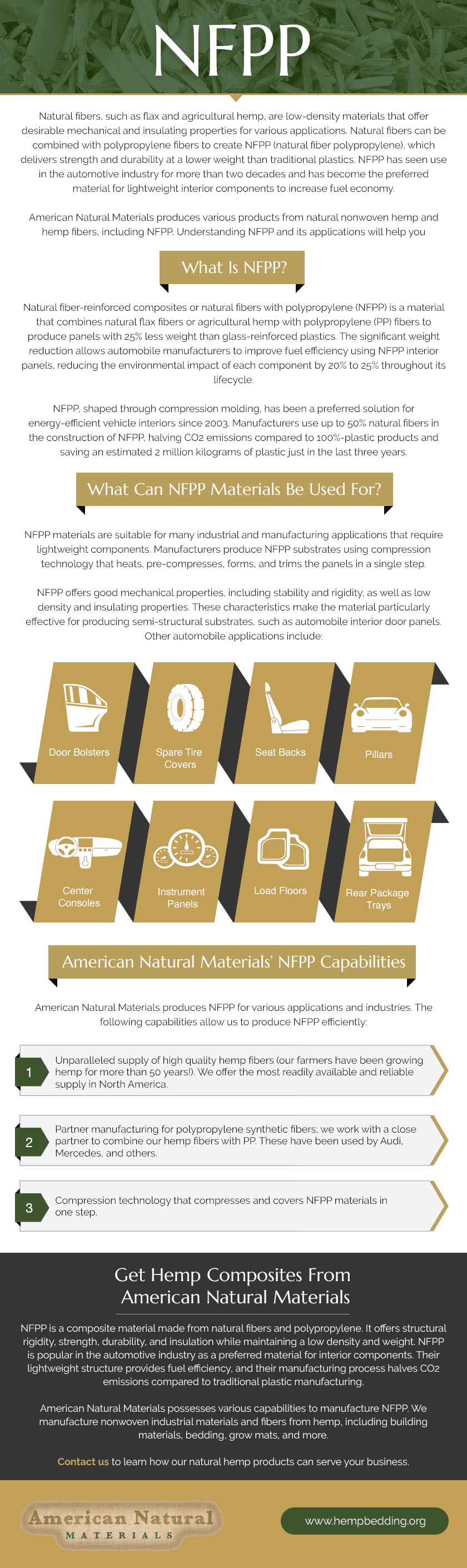

Natural fibers, such as flax and agricultural hemp, are low-density materials that offer desirable mechanical and insulating properties for various applications. Natural fibers can be combined with polypropylene fibers to create NFPP (natural fiber polypropylene), which delivers strength and durability at a lower weight than traditional plastics. NFPP has seen use in the automotive industry for more than two decades and has become the preferred material for lightweight interior components to increase fuel economy.

American Natural Materials produces various products from natural nonwoven hemp and hemp fibers, including NFPP. Understanding NFPP and its applications will help you determine if it is the ideal material for your application.

What Is NFPP?

Natural fiber-reinforced composites or natural fibers with polypropylene (NFPP) is a material that combines natural flax fibers or agricultural hemp with polypropylene (PP) fibers to produce panels with 25% less weight than glass-reinforced plastics. The significant weight reduction allows automobile manufacturers to improve fuel efficiency using NFPP interior panels, reducing the environmental impact of each component by 20% to 25% throughout its lifecycle.

NFPP, shaped through compression molding, has been a preferred solution for energy-efficient vehicle interiors since 2003. Manufacturers use up to 50% natural fibers in the construction of NFPP, halving CO2 emissions compared to 100%-plastic products and saving an estimated 2 million kilograms of plastic just in the last three years.

What Can NFPP Materials Be Used For?

NFPP materials are suitable for many industrial and manufacturing applications that require lightweight components. Manufacturers produce NFPP substrates using compression technology that heats, pre-compresses, forms, and trims the panels in a single step.

NFPP offers good mechanical properties, including stability and rigidity, as well as low density and insulating properties. These characteristics make the material particularly effective for producing semi-structural substrates, such as automobile interior door panels. Other automobile applications include:

- Door bolsters

- Spare tire covers

- Seat backs

- Pillars

- Center consoles

- Instrument panels

- Load floors

- Rear package trays

American Natural Materials’ NFPP Capabilities

American Natural Materials produces NFPP for various applications and industries. The following capabilities allow us to produce NFPP efficiently:

- Unparalleled supply of high quality hemp fibers (our farmers have been growing hemp for more than 50 years!). We offer the most readily available and reliable supply in North America.

- Partner manufacturing for polypropylene synthetic fibers; we work with a close partner to combine our hemp fibers with PP. These have been used by Audi, Mercedes, and others.

- Compression technology that compresses and covers NFPP materials in one step.

Get Hemp Composites From American Natural Materials

NFPP is a composite material made from natural fibers and polypropylene. It offers structural rigidity, strength, durability, and insulation while maintaining a low density and weight. NFPP is popular in the automotive industry as a preferred material for interior components. Their lightweight structure provides fuel efficiency, and their manufacturing process halves CO2 emissions compared to traditional plastic manufacturing.

American Natural Materials possesses various capabilities to manufacture NFPP. We manufacture nonwoven industrial materials and fibers from hemp, including building materials, bedding, grow mats, and more. Contact us to learn how our natural hemp products can serve your business.